AGMT GROUP

Frequency Inverter ST600 1.5KW 400V

Frequency Inverter ST600 1.5KW 400V

Prices excl. VAT plus shipping costs

Prices excl. VAT plus shipping costs

Delivery

Packing

All products are robustly packed in special packaging and shipped as soon as possible via UPS. Within Germany, shipping is free for eShop orders up to 10 kg. All prices and delivery times can be found in the table.

Extras

Customs clearance (goods from 1.000 EUR outside EU): EUR 54 Movement certificate A.TR.: EUR 89 Certificate of origin: EUR 89 Large shipments with pallet: Price on request

Self-collector

Please call in advance.

Click here to see Shipping costs

Couldn't load pickup availability

Highlights

- Power: 1.5KW

- Input current: 5A

- Output current: 3.7A

- Input frequency range: 50Hz / 60Hz ( ± 5%)

- Output frequency range: 0-400Hz

- Voltage: 380V (15%) - 440V (10%)

- Standardised emergency stop function according to SIL2 level (STO)

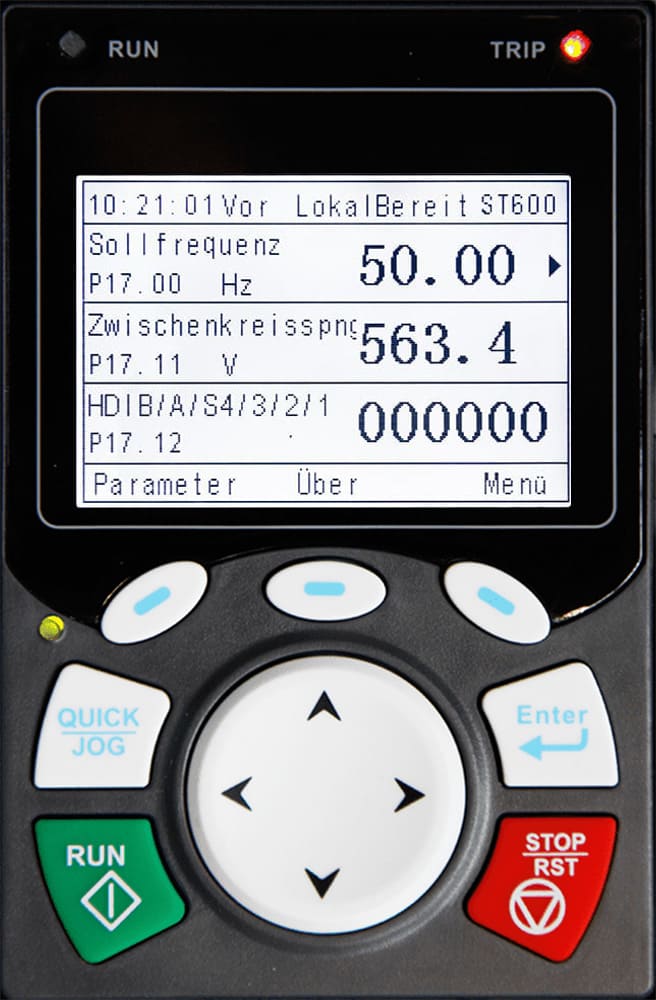

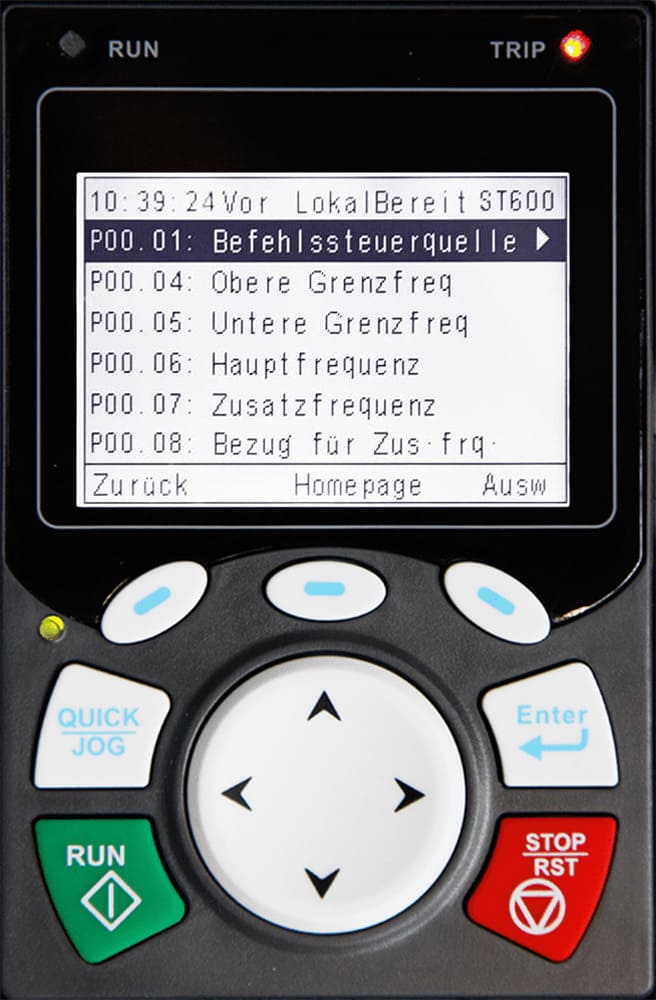

- Graphical removable LCD control panel

- Expandable with WIFI, Bluetooth, ProfiNet/Profibus, CANopen, PG, SPS, IO

- Integrated braking unit

- Integrated EMI Filter C3

- Flexible digital and analogue I/O

- Advanced PID control

- Easy intuitive commissioning and short installation

- Flexible speed setting with panel keys

- Overload capability: 1min 150% / 10 sec 180% / 1 sec 200%

- Auto-slip compensation RS485 interface integrated (control protocol Modbus RTU standard)

- German interactive operating instructions

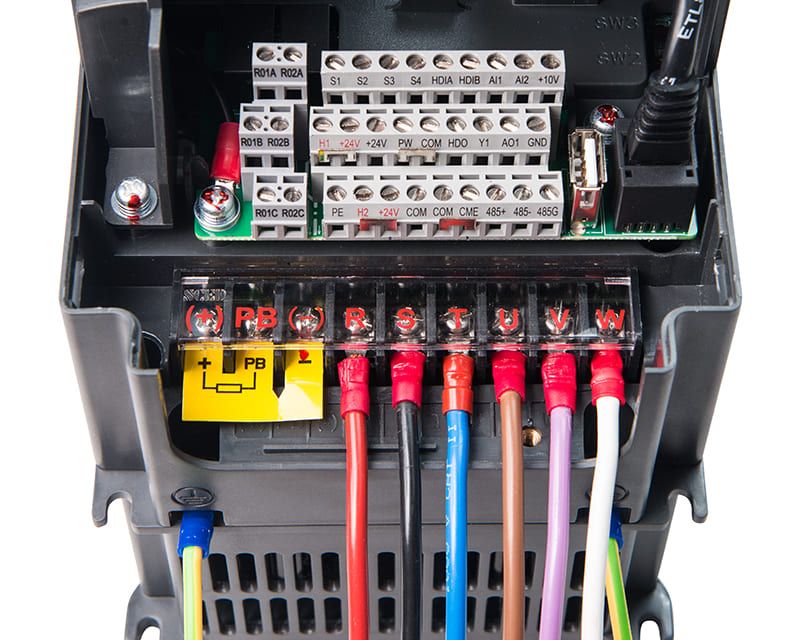

Inputs

Digital inputs |

|

| Programmable digital inputs: | 6, of which 4x max. 1kHz (S1-S4), 2x max. 50kHz (HDIA, HDIB) with 82 input functions |

| Voltage level: | 0 - 24VDC |

| Logic: | PNP / NPN Factory default: PNP (active when the input is connected to +24V) |

| Maximum voltage at input: | 30VDC |

| Number of programmable pulse inputs: | 2 (HDIA, HDIB) |

| Maximum input frequency: | 50kHz, duty cycle 30 to 70% |

| Resolution for frequency control: | 0.1% |

| H1, H2 | Redundant inputs for connection to +24V via normally closed contacts for the STO safety function (immediate interruption of power to the drive if at least one of the connections to +24V is interrupted). In factory setting connected to +24V via shorting jumpers (STO inactive). |

Analog inputs. |

|

| Number of analog inputs: | 2 |

| Type of inputs: | AI 1: 0-10V / 0-20mA AI 2:-10 - +10V |

| Resolution for frequency control | max. frequency * 0.05%, tolerance ±0.5%@25°C |

Outputs

Output (U,V,W) |

|

| Control modes: | U/f characteristic curve / vector control o. PG / vector control w. PG |

| Output voltage: | 0 - 100% of the mains supply |

| Output frequency: | 0 - 400Hz (vector control or V/f - control) |

| Nominal motor voltage: | 400V |

| Ramp times: | 0.0 - 3600.0s |

| Ramp functions: | Linear / S-curve |

| Overload function: | 150% for one minute 180% for 10 seconds 200% for 1 second |

| Carrier frequency: | 0.5kHz - 16.0kHz adjustable |

| U/f curve modes: | Linear / Square / Adjustable |

Digital output / pulse output |

|

| Programmable outputs: | 2; 1 high-speed output, max. 50kHz, 1 open-collector output, max. 1kHz 51 output functions |

| Voltage level: | 24VDC, max. 30VDC, 50mA |

| Logic: | NPN (output is actively pulled against COM or CME) |

| Minimum output frequency: | 0Hz |

| Maximum output frequency: | 50kHz |

Relay outputs |

|

| Programmable outputs: | 2 |

| Clamp number: | RO1A-1C and RO2A-2C: normally open RO1B-1C and RO2B-2C: normally closed |

| Maximum power AC: | 250VAC / 3A |

| Maximum power DC: | 30VDC / 1A |

| Number of functions: | 51 |

Analog outputs |

|

| Programmable outputs: | 1 |

| Voltage range: | 0 - 10VDC max. 5mA |

| Current range: | 0 - 20mA max. load 250Ohm |

| Number of functions: | 32 |

Modbus |

|

| RS485 | Integrated |

Optional |

|

| The optional IO501 expansion card adds 4 digital inputs S5-S8, 1 digital output Y2, 1 analog input AI3 (0-10V/0-20mA), 1 analog output AO2 and two relay outputs | |

Integrated protection concept

- Earth-fault protection

- Over- and undervoltage protection

- Overcurrent protection

- Over- and underload protection

- Temperature display rectifier and IGBT output stage

- Protection against overtemperature

- Overvoltage prevention during braking

- External stop signal

- Safe Torque Off (STO)

- Stop when communication is interrupted

- Detection of abnormalities in the PID signal and PG error

- Input for motor temperature bimetal switch/PTC

- Password protection

- Auto self-test after restart

Display and functions

- Display:

- Frequency, current, voltage, torque, PID, ...

- Error messages

- Key lock / parameter transmission

- Languages: DE, EN

- Error messages:

- Error type

- Output and bus voltage

- Output current

- Setpoint and actual frequency

- Inverter terminal status

- Temperature

- Automatic functions:

- Measurement of motor data

- Voltage readjustment (AVR)

- Active current limitation

- Restart in case of mains failure

- Slip compensation

Enclosure types and dimensions

Rated voltage |

Output power [kW] |

Rated input current [A] |

Rated output current [A] |

Housing dimensions in mm

|

Weight [kg]

|

| 3-phase 400V | 1.5 | 5 | 3.7 |

126 x 186 x 185 |

2 / 3 |

Environment

- Temperature range -10°C to +40°C at nominal load

- Storage temperature -20°C to +65°C

- Humidity 90% RF - without condensation

- Can be used up to 1000m above sea level without power reduction

- Vibration test under 5.9m/s²=0.6g

- Safety level according to IEC61800-5-1/2+A1

- Electromagnetic compatibility according to IEC61800-3

- Protection class: IP20 (EN 60529), pollution degree 2

- RoHS-compliant

- CE-compliant

Scope of delivery

- Frequency inverter ST600

- German operating instructions

Further functions

- Rated motor frequency 50Hz and 60Hz

- Forward and reverse operation

- Controller enable control panel/terminals/bus

- 16 configurable speed levels selectable via digital inputs

- 12 different speed control options

- Continuously adjustable clock frequency: 1.2kHz-15.0kHz (PWM)

- "Open-loop boost mode

- DC brake function (duration, strength, frequency) & JOG control

- Simultaneous control of several drives "Slave-Vector-Control

- Reduced motor noise through precise PWM function

- Avoidance of vibrations due to selectable blocking frequencies

- Variable speed with constant torque

- "Plug & Play"

Brake units and brake resistors |

|

| External braking units are used in applications with heavy loads and rapid load changes on the motor. The braking unit protects the frequency inverter from excess energy in the DC link that is fed back from the motor. This excess energy is then converted into thermal energy by the braking resistors connected to the braking unit and released into the environment. |

|

EMC - Filters and chokes |

|

| EMC filters and interference suppression chokes are also available as additional accessories for each power class. |

|

Bus systems |

|

| Supports many common bus systems such as PROFINET, PROFIBUS as well as Modbus RTU |

|

Digitalisation of drive technology - bus systems, internet and cards

The frequency inverter has standard 485 communication and is flexibly expandable with PG card, PLC card, IO card, ProfiNet, Profibus, WIFI, Bluetooth, CANopen, etc. The PG card uses digital filtering technologies to improve electromagnetic compatibility and enable stable reception of the encoder signal over long distances. Compared to the traditional scheme, the anti-interference performance is doubled. High speed is achieved with 2 x HDI, and high-speed AB pulse is also supported as an input signal.

Preventive maintenance - Continuous improvement of your production

Your electric motor-driven application requires reliable performance. Maximum system availability and operational safety is achieved through customised services, such as wireless troubleshooting via remote access or Bluetooth access using the smartphone APP. The parameter sets can be read out quickly via the USB port. An external uplink allows the inverter's operating curve to be recorded for maintenance and analysis.

Sustainability - energy efficiency and IE2 class according to IEC 61800

Up to 70% of the electricity consumed in industry worldwide is used to run electric motors. Pumps are one of the most common applications and offer the greatest potential for savings. Frequency converters can help solve the challenges of the energy transition. Because at half speed, only one eighth of the energy is needed. You will be interested to know that Sourcetronic frequency inverters already meet the strictest requirements of the IEC 61800-9 standard for energy efficiency and are classified according to IE2.

Share